The agricultural industry is undergoing a rapid transformation, driven by the need for increased efficiency, precision, and sustainability. This evolution hinges significantly on the adoption of sophisticated machinery, from automated harvesters to precision irrigation systems. At the heart of these advanced machines lie motors – the driving force behind their functionality. However, selecting the right motor for a specific agricultural application can be a complex challenge, particularly when faced with the choices between gear motors and servo motors. This article will explore common mistakes agricultural machinery enterprises make during motor procurement, emphasizing the key differentiators between these two motor types and offering actionable solutions to ensure optimal performance and ROI. We'll also touch upon the increasing role of IoT and edge computing in influencing motor selection.

Before delving into mistakes, let's clarify the fundamental differences.

Gear Motors: These are essentially electric motors with integrated gearboxes. The gearbox reduces the motor's high speed and increases torque. They’re known for their robustness, simplicity, and cost-effectiveness. Gear motors are excellent for applications requiring consistent, high torque output with relatively low speed.

Servo Motors: Servo motors are closed-loop systems offering precise control over position, velocity, and torque. They incorporate a motor, a feedback sensor (like an encoder), and a control circuit. This feedback allows the servo system to continuously adjust the motor's output to match the desired setpoint. This allows for incredibly precise and responsive movements.

| Feature | Gear Motor | Servo Motor | |-------------------|-----------------------------------------------|--------------------------------------------------| | Torque | High, constant | Variable, precise | | Speed | Relatively low | Wide range, highly controllable | | Position Control | Limited | Precise, accurate | | Efficiency | Generally lower | Generally higher, especially at variable speeds | | Complexity | Simple | More complex, requires feedback system | | Cost | Lower initial cost | Higher initial cost | | Maintenance | Typically lower | Potentially higher (due to complexity) |

Here are some prevalent mistakes agricultural machinery enterprises make:

1. Focusing Solely on Initial Cost: It’s a common trap to choose gear motors solely based on their lower upfront cost. While appealing, this can be a false economy. The lack of precise control offered by gear motors can lead to inefficiencies, reduced productivity, increased material waste (in harvesting applications), and higher maintenance costs over the machine's lifespan. For example, inefficient steering systems in autonomous tractors can significantly impact fuel consumption and operational costs.

Solution: Conduct a thorough Total Cost of Ownership (TCO) analysis. Consider factors like energy consumption, maintenance schedules, potential downtime, and the long-term impact on productivity. A higher initial investment in a servo motor may be justified if it leads to significant cost savings in the long run.

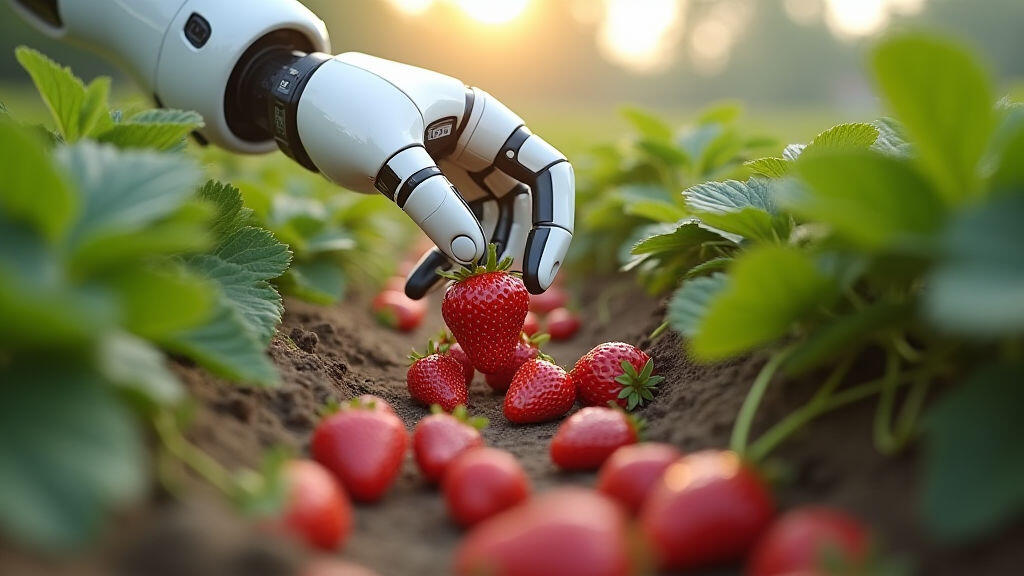

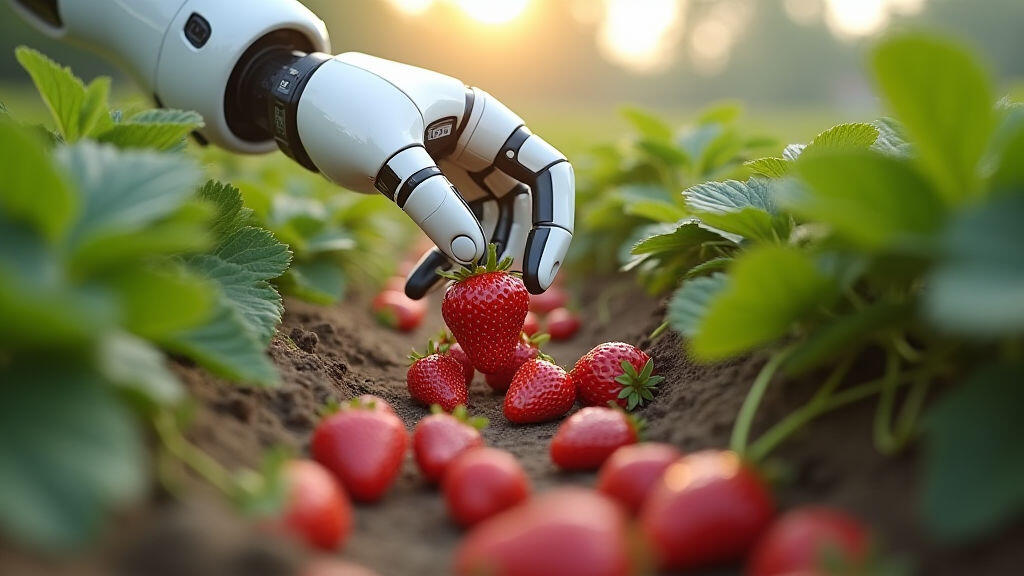

2. Underestimating the Need for Precision: Many agricultural applications, such as precise planting or robotic harvesting, demand exceptional accuracy. Relying on gear motors in these scenarios can result in inconsistent performance and unacceptable quality. Imagine a robotic arm tasked with delicately picking fruits – a gear motor’s inherent limitations in position control would quickly make this impractical.

Solution: Clearly define the precision requirements of the application. If precise positioning and control are critical, servo motors are the clear choice. Leverage advanced sensor technologies and control algorithms (increasingly powered by edge computing) to maximize the benefits of servo motor systems.

3. Ignoring Environmental Conditions: Agricultural machinery often operates in harsh environments – exposed to dust, moisture, extreme temperatures, and vibrations. Standard motors may not withstand these conditions, leading to premature failure.

Solution: Select motors specifically designed for harsh environments. Look for IP (Ingress Protection) ratings that indicate resistance to dust and water. Consider motors with sealed enclosures and robust construction. MES-Drive offers a range of motors with specialized coatings and protective features to enhance durability.

4. Not Considering Power Requirements: Failing to accurately assess the power requirements of the application is a frequent mistake. Underpowering a motor will result in reduced performance and potential overload, while overpowering will lead to unnecessary energy consumption and increased costs.

Solution: Use detailed load calculations and consult with motor specialists to determine the appropriate motor size and power rating. Factor in peak loads and dynamic demands. Modern motor selection software (available from many manufacturers) can assist with this process.

5. Overlooking the Importance of Control Systems: A servo motor's performance is intrinsically linked to the quality of the control system. A poorly designed or implemented control system can negate the advantages of using a servo motor.

Solution: Invest in a reliable and well-integrated control system. Ensure that the control system is compatible with the chosen motor and equipped with the necessary sensors and software for precise control. Modern embedded systems and IoT platforms can greatly simplify control system development and deployment.

The rise of the Internet of Things (IoT) and Edge Computing is revolutionizing motor control in agricultural machinery. IoT sensors can provide real-time data on motor performance, environmental conditions, and operational parameters. This data can be used to optimize motor control, predict potential failures, and improve overall system efficiency. Edge computing allows for data processing closer to the source (the machine itself), reducing latency and enabling faster response times.

For instance, data from vibration sensors can be used to detect early signs of motor wear and schedule preventative maintenance. Furthermore, real-time torque and speed feedback can be used to optimize harvesting processes, minimizing damage to crops. MES-Drive's smart motor solutions incorporate IoT connectivity and predictive maintenance capabilities to enhance operational efficiency.

Choosing between gear motors and servo motors isn’t a one-size-fits-all decision. It demands a careful evaluation of the specific application, precision requirements, environmental conditions, and overall system cost. By avoiding common pitfalls and embracing advancements in IoT and edge computing, agricultural machinery enterprises can unlock the full potential of motor technology.

With the growing emphasis on sustainable farming practices and increasing demands for higher yields, precision agriculture is poised for significant growth. Servo motors, coupled with smart motor management systems like those offered by MES-Drive, will play a crucial role in driving this transformation. The ability to precisely control machinery, optimize resource utilization, and minimize waste will be paramount to success in the future of agriculture.

Leave A Reply

Your email address will not be published. Required fiels are marked